Understanding Safe Moisture Content Grain Storage

Grain storage is a critical aspect of agriculture, significantly affecting overall productivity and profitability. Ensuring that stored grain maintains a safe moisture content is essential for preventing spoilage, pest infestations, and the growth of mold. This comprehensive guide will delve into the importance of safe moisture content in grain storage and provide you with actionable insights to optimize storage conditions for your farming equipment and grain management systems.

The Importance of Safe Moisture Content in Grain Storage

Grain crops contain moisture, and controlling this moisture is vital in preserving the quality and integrity of the grain. If the moisture content is too high, it can lead to severe consequences, including:

- Spoilage: High moisture levels create an ideal environment for bacteria and fungi, which can spoil the grain.

- Pest Infestation: Excess moisture attracts insects and rodents, leading to further grain loss.

- Reduced Market Value: Grain that does not meet safe moisture standards may be rejected by buyers or sold at a lower price.

What is Considered Safe Moisture Content?

The safe moisture content for different types of grain varies. Here are some general guidelines:

- Wheat: Ideally between 12% and 14%.

- Corn: Safe levels are around 15% or lower.

- Rice: Should be maintained at approximately 14% moisture.

- Barley: Recommended moisture content is between 12% and 14%.

It’s crucial to regularly monitor and manage the moisture content of your grain to ensure its safety and quality.

Best Practices for Maintaining Safe Moisture Levels

To ensure the grain retains a safe moisture content, consider implementing the following practices:

1. Optimal Harvesting Timing

Harvesting grains at the right moment significantly influences moisture levels. It is advisable to harvest when moisture levels are at their safest. Conducting moisture tests using moisture meters can provide precise readings to guide your harvesting schedule.

2. Proper Drying Techniques

After harvest, immediately drying the grains to reduce moisture levels is essential. The use of commercial grain dryers or natural drying methods, like aeration, can effectively reduce excess moisture. Ensure your drying method does not damage the grain and maintains its quality.

3. Storage Solutions

Choose the right storage facility or equipment. Grain bins, silos, and sheds should be designed to provide adequate ventilation and temperature control:

- Ventilation: Ensure air can circulate freely through the grain to prevent moisture buildup.

- Temperature Control: Monitor and control the temperature to avoid condensation, which can raise moisture levels.

4. Regular Monitoring

Consistently checking the moisture content of the stored grain ensures that any variation can be promptly addressed. Utilize grain moisture meters for accurate assessments and keep records of moisture levels.

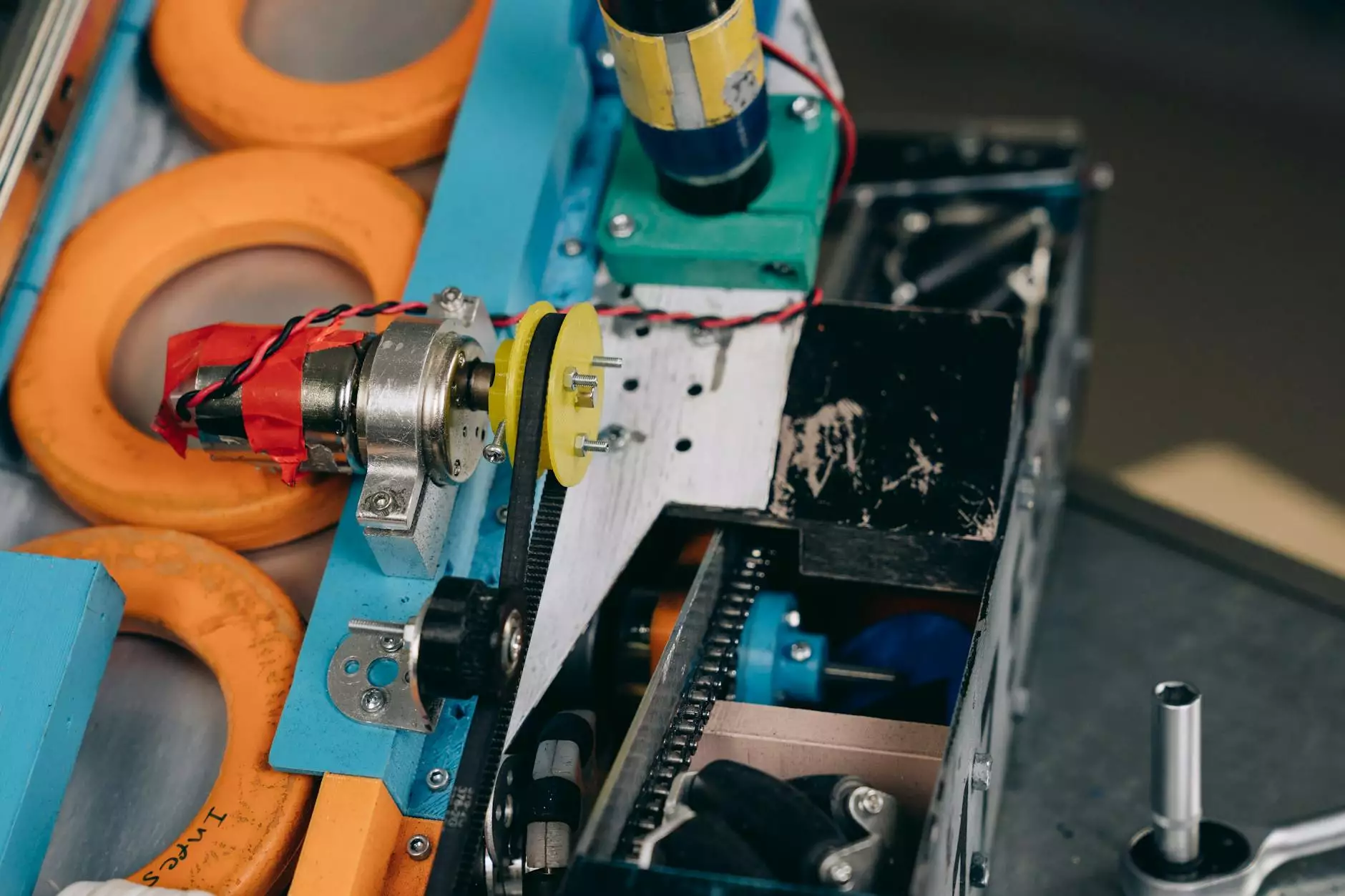

Understanding the Role of Equipment in Grain Storage

The effectiveness of grain storage is heavily dependent on using the right equipment. At tsgcinc.com, we offer high-quality farming equipment repair services and advice on selection. Here’s how to choose the right equipment to enhance your grain storage:

1. Grain Bins and Silos

Investing in high-quality grain bins and silos ensures optimal storage conditions. Choose structures that allow for easy aeration and have robust sealing to prevent moisture ingress.

2. Grain Dryers

Efficient grain dryers are key to reducing moisture levels post-harvest. Explore models suited for your grain types to ensure the drying process maintains grain integrity.

3. Monitoring Systems

Advanced storage solutions now feature moisture monitoring systems that alert you to changes in moisture levels. This technology is invaluable for maintaining safe moisture content without constant manual checks.

Addressing Common Challenges in Grain Storage

While managing moisture is straightforward in principle, various challenges can arise. Here’s how to tackle these common issues:

1. High Humidity Environments

If you are in an area prone to high humidity, consider humidity control systems and invest in dehumidifiers where necessary.

2. Pest Infestations

Implement regular inspection protocols and maintain cleanliness in storage areas to prevent pest problems. Use pest management systems to deter infestations.

3. Structural Issues

Regularly inspect your storage facilities for integrity. Any leaks or weak points should be repaired immediately to avoid moisture ingress.

Conclusion: The Future of Grain Storage

The future of grain storage lies in continual innovation and adherence to best practices. For farmers and grain handlers, understanding and maintaining safe moisture content levels is not just about preventing losses but also enhancing sustainability and ensuring quality produce. By employing the right technologies and methods, it is possible to significantly reduce moisture-related issues and improve the management of stored grain.

At tsgcinc.com, we are committed to supporting farmers with invaluable resources and superior farming equipment repair solutions to enhance your grain storage practices continually. Remember, a proactive approach in managing moisture can pave the way for agricultural success.

safe moisture content grain storage